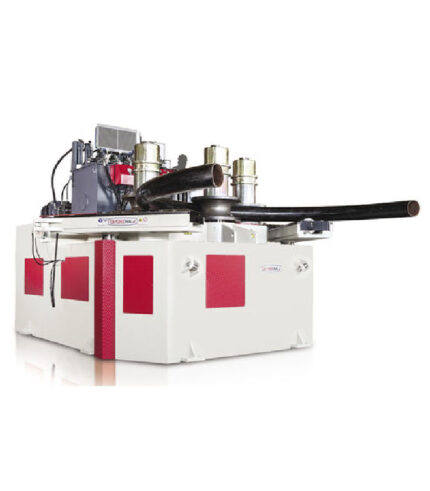

Frame of our machines are made of welded steel (st-52). Roll shaft and bearings are of high quality and robust in terms of bending moment. All 3 rolls are independently driven by hydraulic motors and gearboxes on 3 rolls plate bending machines whose top roll diameter is 230mm or larger.

As for the machines whose top roll diameter is smaller than 230mm, top roll is driven by gearbox and lateral rolls are driven by hydarulic motors independently.

STANDART EQUIPMENT

- Cone Bending Device

- Induction Hardened rolls

- Digital display for both side rollers

- Fully welded steel (ST-52) frame

- Independent moving control panel

- Two bendling speed

- All rolls are mounted in spherical roller bearing

- Drop end opened and closed hyraulically and controlled from control panel. When the drop end is opened, upper roll tilts up automatically.

- Cone opening and closing on control panel

- Central rolls-upper and lower rolls-driven by hydraulic motor and planetary gearbox

- Electro - hydraulic callibration

- Production quality certified by CE, ISO 9001-2008, TESK and TURQUM

OPTIONAL EQUIPMENTS

- Infinitive variable speed of rotation

- Side and central supports for big sheet metal diameters

- Material feeding table with various features

- CNC grapich control system

- NC Playback control system

- Interchangeable top roll for tighter diameters

- Oil cooling system

- Motors in variable voltage and frequency

- CNC

- NC